How to Manage a PP Meeting from a Buying House?

|

| PP Meeting |

What is PP (Pre-Production) Meeting?

PP Meeting is a short form of a Pre-Production Meeting. From its name, one easily can understand or get an idea of the meaning of this Meeting.

The PP Meeting is a meeting before starting the bulk production that discusses details about the barriers to the production process, PP comments, buyer’s requirements, and any construction changes of the particular style to smoothly start the bulk production right the first time. In the PP Meeting style related preventive actions are taken to set the standard operating process (SOP) in bulk production.

A meeting that supplier and buyer representatives perform before going to the production stage to discuss how to avoid possible mistakes in the production stage is PP Meeting.

Purpose of the PP Meeting:

Findings of the size set sample errors or defects (visual, measurement, tests, etc.), pre-production checklist compare against the approved PP Sample. Followed the tech pack instruction and updated PP comments from the Complete QC File. Discussed the production plan up to shipment from the trial cut with the supplier or vendor concerned department head about the work execution and providing the suggestion or solution to start the bulk production is called the PP Meeting.

To conduct a successful PP Meeting Buying House QA needs some documents:

A Complete QC File:

QC file is something that starts from product development to shipment of the finished goods. QC file or production file or style file is required for the Quality, Production, Technical & Merchandising Departments, especially for the Quality Department to verify all quality parameters ensured in all stages of garment manufacturing. QC file is necessary to start the bulk production.

In a word, the necessary supporting documentation needed to handle a full export order quality is the QC file.

|

| QC File |

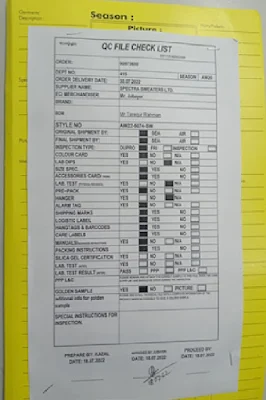

A complete QC file or Production File should include below essential items or documents:

- Check List.

- PP Sample (Latest Sample) comments.

- Tech Pack or Technical Sheet.

- Measurement Size Spec.

- How to measure.

- PO Sheet or Purchase Order Sheet.

- Fabric details and references for all kinds of fabric.

- Fabric details and references for all types of fabric.

- Test report.

- Barcode Verification sheet if required.

- Trim card.

- PP sample.

- B2B or Online Packing list.

At first, Buying House QC or QA studies this complete QC file or Production file to know the buyer's requirement of that particular style.

Size set Samples:

A complete size set sample is needed to conduct the PP Meeting. Each color and each size minimum of one sample is called a complete size set.

Sometimes a Style includes more color or more sizes. In that case, the supplier or manufacturer made a jumping size set. The jumping size set is as every alternate size sample.

|

| Size set sample |

Example of Jumping size set:-

Size in the style is- XS, S, M, L, XL, XXL, XXL

Suppliers are making the size sets like XS, M, XL, XXL

If More colors and more sizes are in the style, suppliers are making mixed-size sets:-

Sizes are in the style- XS, S, M, L, XL, XXL, XXL

Colors are in the style- Black, Navy, Red, and White.

Normally Suppliers do not make all colors full-size sets. In this case, suppliers are making a full-size set in one color. The remaining colors are making jumping sizes or covering sizes by covering all colors.

Important Documents evaluation:

After the study of the complete QC file, Buying House QA checks the styling with the approved PP sample, tech pack, and PP Comments. Buying House QA takes snapshot evidence to make the PP Meeting report.

Buying House QA has to inspect or evaluate the full-size set visually to find the defects, check the color shading, do a pull test if applicable, check the fabric weight, take the measurements and check the pattern.

During the check or inspection of the size set, Buying House QA or Inspector also checks below the documents that already did the supplier:-

- Fabric inventory and inspection report.

- Accessories or trims inventory and inspection report.

- Shade blanket or shade card.

- Shrinkage test report.

- Crocking test report.

- Button pull test, pinch test report.

- Heat transfer sticker test report.

- All fabric rolls GSM test report.

- Barcode verification report.

- Fabric relaxation report.

Participants in the PP Meeting:

PP meetings can be held on factory premises or by buying houses. Below respective people has to be present at the Pre-Production Meeting:

- Buying House QA.

- Concern Merchandiser (Buying house & Factory).

- Quality Manager.

- Production Manager.

- Sample Manager or Incharge.

- GPQ

- Cutting Manager.

- Store Manager.

- Finishing manager.

- CAD Incharge.

- Production Ingharge.

- Sewing Supervisor.

- Planning Manager.

- Maintenance Manager.

- IE Manager.

- Embroidery or Printing Manager.

- Wash Technician.

PP Meeting Discussion and Report Making:

After reviewing, the complete QC File, all the supplier reports, and the size set sample Buying House QA have to brief the supplier on expectation requirements and collect the evidence to make and publish the PP Meeting report.

Post a Comment