How to Make a QC File?

What is the QC File for Garments?

QC file is something that starts from product development to shipment of the finished goods. QC file or production file or style file is required for the Quality, Production, Technical and Merchandising Departments, especially for the Quality Department to verify all quality parameters ensured in all stages of garment manufacturing. QC file is necessary to start the bulk production.

|

| QC File |

A QC file is such an important part of garment manufacturing, a size set sample cannot be cut without approval from the buying house.

What documents do you need to make a complete QC file?

A complete QC file should include below essential items or documents:

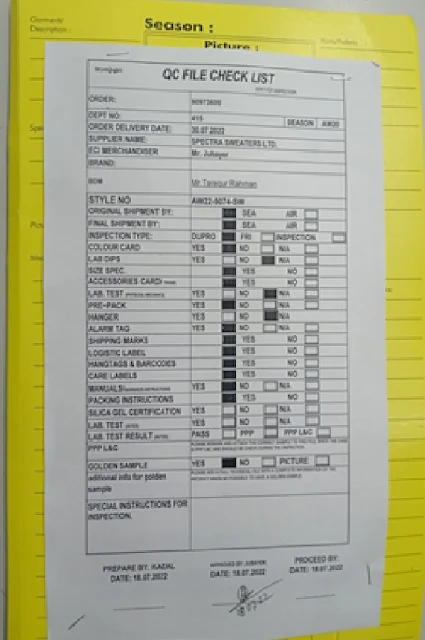

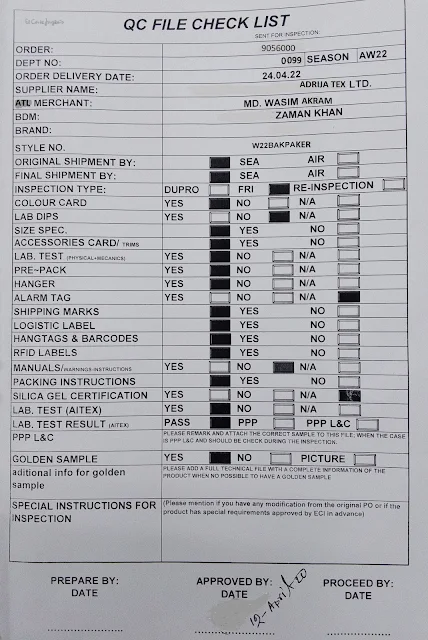

1. Check List:

In the QC File checklist, you will find details about all the required information or instructions for the order. It has included all the related information in the particular order or style from Lab dips to shipment mood. Actually, this is the summary view of the order of the QC file.

2. PP Sample (Latest Sample) comments:

It must have to include the updated PP sample Comments (Latest Sample) in the QC File.

in the QC File. Suppose, Buyers sent PP sample ((Pre-Production sample) comments and later on they added new comments and asked to follow them

in the production. But if the Merchant is not aware enough to include additional comments in the QC file Production file or Style file then production people may not follow the latest comments or instructions. The Merchandiser is only the person who knows the new instructions because he is only communicating with the Buyer from a Buying house, Sourcing office, or Garment industry.

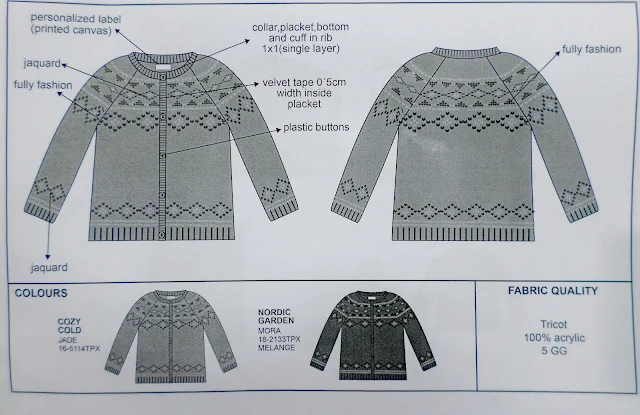

3. Tech Pack or Technical Sheet:

|

| Tech pack |

It contains the following important information and more:

a) Product Summary

b) Technical Drawing/design sketches

c) Measurements/spec sheet

d) Colors Pitching

e) Care Instructions

f) Art-work placement

g) Fabric specifications

h) Bill of Material

i) Material Images

j) Construction details

k) 3D Images and Assets

l) Comments and Feedback

m) Packing instructions

Breaking Records: Thirty Million Users Embrace Meta's Revolutionary Threads | LTTBNews

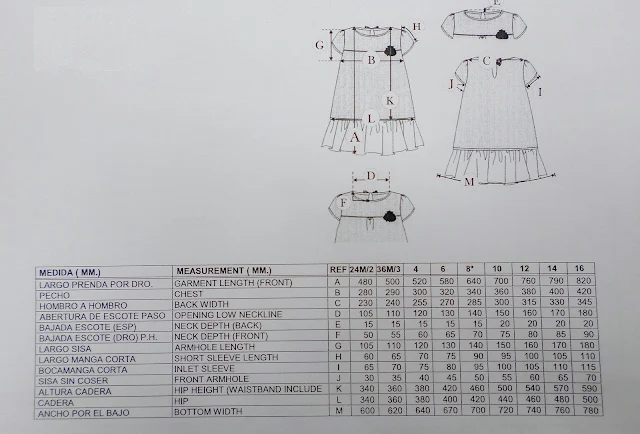

4. Measurement Size Spec:

To ensure that a finished garment will fit properly, it is important to take the

following body measurements, so that suppliers vendors, or production

people can determine what size they should make.

|

| Measurement Spec |

5. How to measure:

each point. Each POM (point of measurement) should have a sketch or image

that shows exactly how to measure the specific point on the garment.

There are no such industry standards for garment measurements. Standard

measurements are derived from the body type. Yet, there are standard

measurements that people follow based on their body type. In general, people

follow different measurement standards in different parts of the world.

what the standard is for buyer-specific brands. This is also important as the size

spec because if how to measure is not provided in the QC file then the

production garments will go out of tolerance due to misunderstanding of

the way of the measurement.

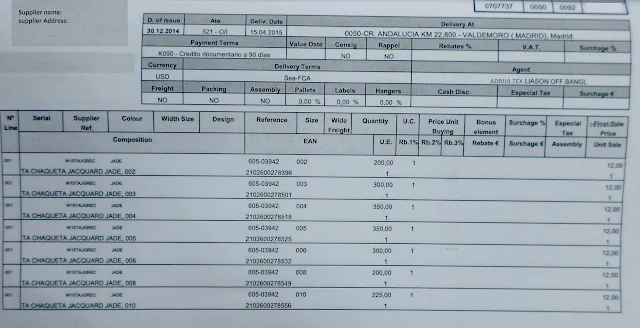

6. PO Sheet or Purchase Order Sheet:

a document commonly used in garment manufacturing to execute garment export

orders and shipments.

Basically, the PO sheet contains the information of confirmation of the buyer order.

To clarify some important manufacturing and technical issues buyer provides the

PO Sheet.

A purchase order (PO) sheet is necessary for every department of the Apparel

Industry. Without a PO sheet, you will not be able to know about your shipment

date, shipping destination, excess ship or short ship tolerance, and payment

term. For that PO sheet is such an important document of style confirmation.

Sometimes buyers update the PO Sheets with a new delivery date if asked for

an extension. But Merchandisers if not careful to check the quantity along with

the size ratio then big mistakes may wait until later. Because sometimes buyers

change the quantity or ratio without any prior notice. So QC File Production

file or Style File should be added with the correct and updated PO sheet.

|

| PO Sheet |

The basic information included in the Purchase Order (PO) sheets are as below:

1) PO Number

2) Department Number

3) Style/Lot Number

4) Order Quantity

5) Shipment Date

6) Unit Cost

7) Total Cost of that PO

8) Factory / Supplier Name

9) Vendor Name

10) Shipping Address

11) Overseas Port reach Date

12) Sourcing Agent

13) Shipment Terms

14) LC Number

15) Fabric Supplier Name and Code

16) Fabric Content

17) Exit Country Port

18) Trims and Accessories cost

19) Product Category

20) Season

21) Description

22) Goods Description

23) Color Name

24) Color reference

25) Barcode Number

26) Size and colour-wise Order Quantity

27) Packing information

28) Transaction Policy

29) Payment Terms

30) Necessary Instruction

31) Terms and Conditions

32) Excess-ship Tolerance

33) Short-ship Tolerance

7. Fabric details and references for all kinds of fabric:

different fabrication with different colours or quality fabric swatches.

There should be included shade bands of all colours in the QC file. it has also

mentioned which lots are accepted and which are not. If there is a contrast color

combination it should be mentioned in the QC file. Moreover, fabric swatch from

bulk has to be included in the QC file, so that production people will not be confused.

|

| Fabric Swatch |

8. Print Strike off/ embroidery strike off or artwork:

strike-off or artwork with size grading in the QC file. It would be more fruitful if the

artwork or strike-off included colour print in the QC File.

Windows 12 list of things to get

9. Test report:

Reach test, SSP test, etc. to do their nominated 3rd party. Those test reports

must be included in the QC File.

Besides this, whatever the normal tests performed in the garment industries

internally like Shrinkage test, crocking test, Fabric weight test (GSM), etc. should

have been included in the QC File.

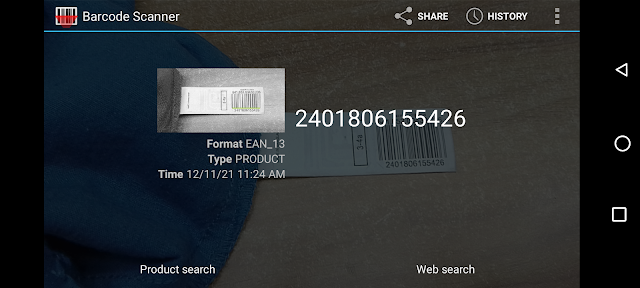

10. Barcode Verification sheet if required:

poly stickers, hangtag, carton stickers) are important to add to the QC file or

Production file or Style file with all the reference numbers that should have been

provided.

Some Buyers mentioned the specific Barcode verification format like EAN-13

and Code-128. So, it is important to include it in the QC file and QC will verify it

and match the EAN code with the PO Sheet.

|

| Barcode verification photo |

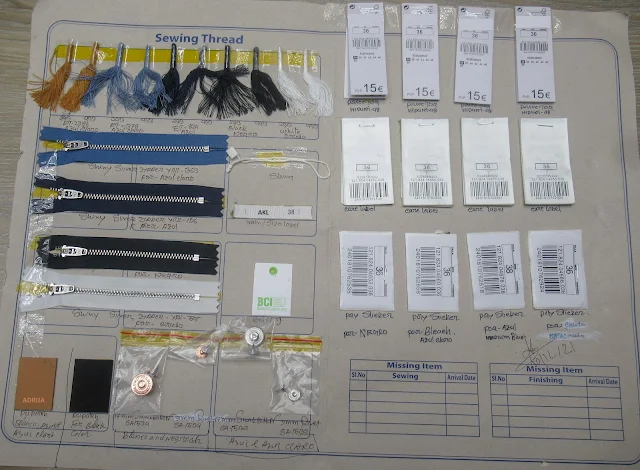

11. Trim card:

items of accessories which items or accessories are used in that particular style.

Fabrics-trims for specific colour and style, specify what colour and code number

thread/zipper/label to use for specific styles and colours.

A trim card helps Garments QC and the production team use the correct fabrics and

trims in every style what exact fabrics and trims want garments buyers.

The Trim card must contain an approved sample of trims such as buttons, lace,

sewing thread, main label, care label, zipper, hangtag, price tag, poly bag,

hanger, poly sticker, shipping mark sticker, etc.

|

| Trims card |

12. PP sample:

development of production in garment factories prior to starting the bulk

production. This sample is made to learn about the style, functionality,

construction, machine requirements and production processes to be used to

make a quality product.

As per buyer instruction, the PP sample is made with actual fabric, trims, and

accessories of the style before the bulk production and it must be sent to the Buyer

to get approval. Without buyer-approved PP samples, garment industries or

vendors could not start bulk production. By making PP samples apparel

industries can learn what all difficulties may come at the time of bulk production.

PP sample must be included in the QC file. If possible color wise PP sample must

provide in the QC file production file or style file. If any changes are required

in the production which is missing in the PP sample then the responsible or

The concerned merchant has to write comments on the sample on what is needed

to add or remove.

13. B2B or Online Packing List:

information about the shipment, including how it's packed, the dimensions,

description, quantity, and weight

package and it may be attached to the outside of the package with a copy inside.

Each packing list must refer to the shipment being shipped and the line item

totals must match the applicable commercial invoice.

Some buyers are using the B2B portal or online packing list. So they provide

the online packing list and it is included in the QC file so manufacturers can

follow that to make cartons.

It is essential to check the inspected style’s details requirement of the Buyer.

Some of the Buyer’s Golden Rules are “No complete QC file, No Inspection”.

إرسال تعليق